“Change will not come if we wait for some other person, or if we wait for some other time. We are the ones we’ve been waiting for. We are the change that we seek.” -Barack Obama

At this point, you’ve read Part I of The Code, and were interested enough to read Part II. You may be on your way to creating your own code, or you are unsure of how to continue and need some inspiration or examples. As a disclaimer, there is going to be a limit to how personal I get here. This blog is not about my personal life, it is merely about the style by which I live. Also, you will learn that I am not a pro at this. I am still learning, tweaking, and improving. The creation of this Code was a way to see what a better me might look like, and to strive to live up to that image, always.. To that end, I am a work in progress. I did not write this code to arrogantly display how well I live. I have no shame in disclosing that I fail in the execution of my own code, a lot. That’s precisely why I wrote it, to improve. Though this Code has allowed me to grow substantially, I have work that remains, and I hope it’s never done.

1. Live to Code

Iteration is the magical process by which we get to try again and again, having learned from our mistakes. We can say “if I knew then what I know now…”, and with iteration, we DO know! When we improve upon something we’ve already improved upon previously, growth becomes exponential.

Now that my Code has been created, I simply execute it. There is no real trick there. I just live it, then I live it again. If I see an area of The Code that needs a tweak I make a change. If I see an area of myself that needs improvement, I do the work, and if necessary, add it to the code so I can be sure that work is being tended to regularly.

I use the phrase “Live to Code” as a mantra. When I find my mindself saying; ”I can do that tomorrow”, I respond with, “Live to Code.” It’s easy to justify putting something off, especially if I’ve been working hard and I’m tired. I deserve a break. When I repeat the mantra, it elevates the urgency of the matter. It’s no longer a simple, justifiable procrastination. It is now me breaking my oath. Being disappointed in myself is a far greater punishment than a pile of delayed chores as a result of laziness.

2. The Temple

As far as “keeping things picked up”, I’d like to say I’ve got this one figured out. However, my mom will read this and beg to differ. I do struggle with tidiness, but not anywhere near as bad as I did. Like I said, I’m a work in progress. Living in a camper has required my improvement here. I have a way to go yet, but this Code is changing “picking up” from a chore, into a simple, mundane part of daily life that requires less and less thought or effort. Minimalism helps me solve this problem before it even starts. It’s harder to engage in the game of clutter if you have fewer players.

Before I give any item a home in the camper, it has to pass some tests. Do I need it? Really? No, really? If I’m honest, the answer is sometimes no. I just “want” it. I have to carefully ponder each purchase. Even if I already own it, does it need to live inisde the camper? Luckily, I have some storage options that make items less accessible, but still available.

Items that come into the camper have to “audition”. They have 30 days to prove their worth. If they don’t prove to be as useful or necessary as anticipated during this probationary period, they go away. If I feel they haven’t had a real chance to shine, I can extend the probation for another 30 days. I believe in patience and a fair shot, so under rare circumstances, I can extend the period once more (especially if the delay is my own fault). If I don’t find a real use for something in 90 days, I don’t need it enough to keep it around.

Finally, I try to make sure the things in my life serve more than one purpose. If it serves only one, it better be a damn important one.

3. Be A Good Citizen

If I have any one shining quality that I exhibit without much thought or effort, it’s being kind. I almost can’t write about how I participate in this aspect of The Code, because it is simply my nature. I don’t actively execute any skill or process. I simply engage in the philosophy of right action. I try to determine what the next right thing is, I weigh the consequences of my actions on myself and others, and I act as appropriate. I always concern myself with the feelings of those around me, even strangers.

In fact, I have often been described as “too nice”, or “nice to a fault”. I have a co-dependent nature. I am a people pleaser. I often make sacrifices to please others, when I really should take a stand and communicate my own needs. But being a man of few needs, that actually causes very few and very rare problems.

4. Work, Work, Work

I used to transfer my clean clothes out of the dryer and into my hamper. Then I lived out of the hamper. Dirty clothes went on the floor, on account of the hamper being full of clean clothes. When the hamper was empty, it was laundry day. The dirty clothes on the floor went into the now empty hamper for transport to the washer. Today, I fold my clothes as they come out of the dryer. That might seem inconsequential to you, but to me it means that every atom of my being has been affected by this Code. I was the undisputed champion of half done things.

Today, I don’t start the task until there is some sort of plan, and that plan has to include finishing. If the finish is not the end (i.e. there is more work to do on that task another day) I need to decide which tools/materials get put away, and which stay out for a quick start next time. I also HAVE to have a Plan B, ALWAYS. Plan A is not complete, without Plan B. My best plans can and will get derailed by situations out of my control. If I have a plan B, I just shift gears and move on. If I don’t, I get frustrated by the unforeseen issue, I feel lost in my day, and I lose all motivation. Plan B need not be elaborate. Often, plan B is simply the next task on the list, or the first task of the next project.

5. Self Care

To avoid getting too personal, I’m not going to get into a lot of detail here. For me, I have a hard time slowing down. The “what’s next” attitude leads to productivity, but next is exhaustion, then overload, then turning off and tuning out. I try build down time into my plans. When I do this, down time is not being lazy and giving up, it’s just another chore on the list. As I go through the day, I have that down time to look forward to. If I have followed my Code, then the day will have gone as good as possible. It may not have been a great day, but if I honestly tried my best, then that is OK with me. I can wind down happy.

A LOT of my self care plan revolves around my dietary choices. It would take too much space to get into the details here, so I will merely summarize. I eat no meat. I eat very little dairy. It has been a year since I made that choice. I had to severely change my snacking choices. Snacking is a very sneaky game that catches you off guard. I try to avoid processed foods and GMOs. I try to buy organic, but I’m not a stickler about it.

I no longer buy “food”, so much as “ingredients”. I can get a range and abundance of vegetables for cheap, but that means that I HAVE TO COOK. With no microwave, and only “ingredients”, I’m forced to spend time in the kitchen. Of course in my tiny camper, the whole place is basically the kitchen (my counter space is literally 5 inches x 24 inches). With practice and a plan, it takes VERY LITTLE time to do this. The cost; I watch ONE less episode of some show I’m streaming. The benefit; priceless. People who complain about the time it takes to cook should reevaluate that. At first, it does take time, until you develop your menu and process. Healthy eating is not expensive if you’re willing to spend time cooking. My diet is my health care plan, so it is far more valuable than almost anything else I might do with that time. Plus, my simplified groceries save me a lot of money. I also like to grow my own food, but you already knew that.

I don’t exercise. Some of my endeavors are a bit physical, and in the summer I hike, that’s about it. I do some Tai Chi, and I’m gearing up for some Yoga, but those are very low impact. Still, my diet and limited activity has already shed 40 pounds, with hiking season yet to come.

Diet and exercise are often the bane of a person’s existence, but I have tried to flip the script and find something that works for me, avoiding much of the sensational and junk science. It’s no longer a chore, or a necessary torture to eat healthy. It has taken me a long time to find the food that really works for me, but with patience and curiosity, I got it pinned down. It still shifts often, but not drastically. It would have been a quicker process if I had previously taken better notes (see number 7).

6. Be Curious and Playful

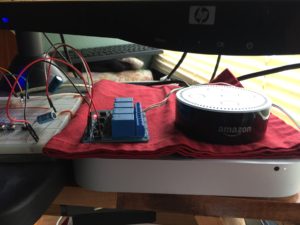

I love to mess around with stuff. I love to make things. I love to hack or tweak pre-made things to better serve my needs. I love to learn new things. When I understand it just a little, I like to throw in bizarre variables, just to see the results. I like to try things even before I really know what I’m doing. I’m going to learn more from a premature and failed attempt then I would spending that same amount of time reading about it. I EXPECT to fail. I EMBRACE it. I sometimes fail ON PURPOSE. With failure built into my process, I am not afraid of it. Without that fear, I am free to cash in on the reward that risk often brings.

I was always very shy. I still am, except in situations where I have been around people long enough to become comfortable. It makes an active social life difficult for me, but The Code has helped there as well. Some months ago, I had a talk with a friend. He had his knee replaced, and he healed very quickly. He credited having quit smoking with aiding his recovery. I asked him how long it had been since he quit. In my mind, it had been about 6 months. He replied, “A year and a half.” To me, that meant the last 6 months of my life had actually been a year and a half. It was passing by, and quickly. “Enough is enough,” I said. Avoiding details I’ll say that there is this “social thing” that I NEVER do, but the next day, I took a risk and did it. It basically failed. But that’s OK. I was proud to have done it. It was The Code in action. I was curious and playful, I embraced the failure, and I moved to the next thing to the best of my ability.

7. Keep a List

I absolutely have to write things down to remember them. It’s strange, because I have a great memory. I have some sort of semi-eidetic or photographic memory. When I take a test, I can often see, somewhat clearly, text or charts from a book. It’s very flawed and unreliable, but it got me a 4.0 in college without a lot of effort. Despite that, if you tell me to get three things at the store, I might remember one of them if I remember to go to the store at all. My brain spins too erratically to retain that type of information.

Despite my “geek” blood, I’m not a big fan of productivity apps. I have wasted more time playing with apps than I can to recount. They are often very feature rich and complex, which means there is a learning curve. Those apps are amazing if you need those features. I don’t. I like to keep it simple, and that’s often a struggle. I work too organically to be a slave to software. I DO use apps, I just don’t rely on them for everything. I use an app called Trello for a big picture view of my life, and my day to day affairs play out in analog on small pieces of scrap paper.

What’s important is that I log all of the data my life generates. Data is the poetry of a process. Logging it means I can repeat that process (and success) rather than start from square one over and over. I have a notebook for all of the data I gather (except for data from my garden or thermostat, which is digitally created and automatically logged via software). The book is called The Camper Empirical. It’s sectioned off for different data. Categories include; propane purchases, recipes, spending on food/gas/etc…, dietary thoughts and experiments, etc… It’s important to keep this data collected, not scattered.

8. Accountability

We all play the victim sometimes. We like people to come rescue us. It’s comforting. But it gets us nowhere. It solves nothing. And it gets old. Fast. People around us will stop coming to our aid when it’s the only card we have to play. I truly believe that we play a role in EVERYTHING that happens to us. Even if we played no role in creating a scenario, we control how we react, or if we even react at all. Regardless of fault, I am ALWAYS accountable for my response. The world judges us on our actions, not our thoughts or intentions. Our thoughts will gain us no ground if our actions are not congruent. On a daily basis, I look at my actions and the role I played in the days events. If I performed poorly, I try to do better, and apologize to someone if need be. If I can honestly say I tried my best, than the day really could not have gone any better. I just have to recognize that “my best” is not a constant. It’s a variable. Life is an algebra problem. The solution is found by balancing the equation. If the variable of my performance throws the balance off, I can try to balance it out somewhere else or try better the next day. The trick is to actually try. I can always say “I’ll do better tomorrow”, but if I never actually try, I’m just using it as a scapegoat to get away with another bad day.

9. Spirituality

I was taught to keep the details of my spirituality to myself. If I divulge the details, especially to the uninitiated, it arouses their skepticism. I hold the belief that we are all connected, so any skepticism you feel about my beliefs, I feel as well. But I can still walk you through what my path has looked like over the years.

At 19, on the streets of Boston, I met a “missionary” of sorts. This gentleman was traveling the country on bicycle, spreading a message of religion. I was curious how such a journey was funded, and he said that the Lord provided for him. I didn’t believe any of that. Of course, what he meant was that the Lord put people in his path that fed him and gave him places to stay. Still, I didn’t buy it. All of this is irrelevant, except that it got me thinking about what I believed or didn’t believe. I spent a lot of time in the Boston Public Library, with a table full of books on everything from Atheism to Eastern philosophies. I knew pretty quickly that I was not an atheist, but the Christian ideology didn’t speak to me either. I stumbled upon a translation of the Taoist text, the Tao Te Ching. It described an outlook on life that I already had, so I went with it. I can’t say I began “practicing” Taoism then, but I enjoyed it’s teachings and aspired to live up to it’s ideals. A few years later, I saw fit to get the Chinese characters “Wu” and “Wei” tattooed on me (Wu Wei being the primary Taoist philosophy of “inaction” or “without action” or “right action” or “effortless action”). It would be many years until I truly engaged with Taosim in any serious way, when I found myself newly sober and thirsting for a connection. I quickly found that Taoism left something to be desired for me. I learned a lot from Buddhist thought, it was very practical and digestible. But Buddhism proved to be only a stepping stone to the Hindu teachings that provide the majority of my spiritual life today. The Hindu teachings are in keeping with almost any religion you can imagine, it has a very universal quality. I used to get worked up over a lot of things. Hinduism teaches me to slow down, and just be. It teaches me to laugh at myself, even when everything seems to be going wrong. Especially when everything is going wrong. It keeps me open to lessons at every turn.

This thing we call “self” is like a box containing a collection of life experiences. We are but spiritual beings experiencing the world through that self, and realizing this, we get to choose what experiences we collect in that box.

10. Persistence

Iteration, iteration, iteration. Do it again, then do it better, then do it better still. There is a phrase “fake it ‘till you make it”. If you do something enough times, you WILL get results. Even if you don’t mean it at first. Even if you’re full of shit. Even if you don’t believe it. I cannot truly engage in the process of life without being changed by it. So long as I engage in a process that is positive, so will the change be. I just keep doing it.

All 10 pieces of The Code play together. If I use the other 9 parts of the code, the persistence pays off right away, all the time. I make a plan, I write it down, I work toward goals and keep notes on my process and the results. I take playful but calculated risks. I take care of myself and my space as best I can. I try to adhere to my spiritual principles in the process. I remain accountable and teachable. I do this over and over.

Notice the bookends here. Step One is to “Live to Code”, a repeated commitment to the ideals you have set forth. Step Ten is “Persistence”, a repeated commitment to the ideals you have set forth with a slant toward always improving. The Code begins and ends with iteration.

Further reading:

Adam Savage: 10 Ground Rules for Success: Watch – Read

Essential: Essays by The Minimalists – Joshua Fields Millburn & Ryan Nicodemus

The Four Agreements – Don Miguel Ruiz

Zen to Done – Leo Babuata

Lots of other things took place. I fixed all of my screens. I got a new porta potti (the valve started to leak on the old one, not a situation you let linger). I hung some Tibetan prayer flags. Despite being a loner (maybe even a “recluse”?), I learned what its like to navigate this small space for an extended time with another being. I found it to be not only possible, but pleasant. It takes a sort of graceful dance of body and mind to make it work, but it works. This applies to a relationship of an intimate nature, mind you. I don’t think I could tolerate an extended guest otherwise. It also helps if the person is on the same lifestyle wavelengths as you. Though that experiment has drawn to a close, it held many profoundly important and worthwhile lessons.

Lots of other things took place. I fixed all of my screens. I got a new porta potti (the valve started to leak on the old one, not a situation you let linger). I hung some Tibetan prayer flags. Despite being a loner (maybe even a “recluse”?), I learned what its like to navigate this small space for an extended time with another being. I found it to be not only possible, but pleasant. It takes a sort of graceful dance of body and mind to make it work, but it works. This applies to a relationship of an intimate nature, mind you. I don’t think I could tolerate an extended guest otherwise. It also helps if the person is on the same lifestyle wavelengths as you. Though that experiment has drawn to a close, it held many profoundly important and worthwhile lessons.