![]() The coolest part of my trip to the White House was the discovery of the Food Computer. This device is the small scale prototype for a much larger project taking place a the MIT Media Lab. It’s the work of Caleb Harper who is behind MIT’s Open Agriculture Initiative. The project has several aims. Ranging from educating kids about food (where it comes from, how it grows, etc…), researching how to grow better food, and of course, feeding people.

The coolest part of my trip to the White House was the discovery of the Food Computer. This device is the small scale prototype for a much larger project taking place a the MIT Media Lab. It’s the work of Caleb Harper who is behind MIT’s Open Agriculture Initiative. The project has several aims. Ranging from educating kids about food (where it comes from, how it grows, etc…), researching how to grow better food, and of course, feeding people.

Enter, the Food Computer

The PFC (Personal Food Computer) is the open source hardware and software system being developed to help change our food future. In layman’s terms, it is a system that controls all aspects of the plants environment over its whole lifespan. Since different plants have different requirements, the system uses a “climate recipe” (which is simply a series of instruction for the computer) designed the plant in question. Basically, you plant a seed (or a started seedling), select the climate recipe, and press play. The machine will maintain the right temperature and humidity, it will provide the proper nutrients, it will cycle the lighting, it will do everything the plant needs. Then you eat it.

How does it work?

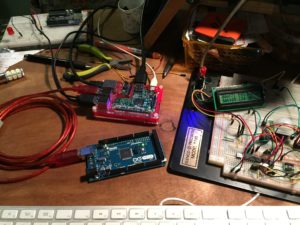

So, as you might expect, it’s a bit more complicated. There is quite a lot going on under the hood. Here’s bit of geek-speak; It uses a Raspberry Pi as it’s brain, and an Ardunio Mega for the heavy lifting. The Arduino controls the mechanical bits like pumps, and relays, and monitors the array of sensors. The sensor data is passed to the Pi where the climate recipe can tell the Arduino when to perform necessary functions. For example, a pH sensor tells the system when to raise or lower the pH, and a peristaltic pump can supply a solution to make that change. It also does this with the nutrient solutions electro-conductivity, among other things. You can control CO2, Dissolved Oxygen, and nutrient solution temperature. So, the pant receives everything it needs, precisely when it needs it, (ideally) without human intervention.

As we speak (December 2016), the PFC V.2.0 is being released. The original version was more difficult and expensive to build. V2.0 is working to change that. It’s an alpha release right now, so there is still work to be done to make it as cheap/easy/accessible as possible. Being open source, anybody can download the plans and the software to build one. You can contribute your ideas to make it better. The release of the plans is an ongoing process, so don’t expect a simple plug and play approach just yet.

So where is this headed?

As the PFC becomes more accessible, more people will build them (including schools, some are already doing so). The plan is to make kits available for purchase to simplify the part sourcing. As the user base increases, a database of climate recipes will amass. You can download a recipe that suits your needs, or you can experiment and upload your own results for others to use.

Whats really exciting is the opportunity for knowledge. Caleb described to me how his team freeze dries the resulting plants and places them in a spectrometer to see the nutrient/chemical break down. They can change growing variables and see the direct results of those variables on the plants chemistry. They can stress the plant in very specific ways (light or nutrient starvation, bacteria introduction, pH/EC shifts) to see what chemical defenses it puts up, and how that changes the nutrient/chemical properties. These things affect the flavor, the nutrition, the shelf life, etc… The best part is, IT’S ALL REPEATABLE. A good result can be downloaded and recreated by anyone, anywhere, with a PFC.

Food Servers and Beyond

The PFC is admittedly small. You aren’t going to feed your family with it. It’s footprint is about 3 feet wide by a foot and a half deep, and it stands maybe 3 feet tall. It could fit on a counter or a small table, and can grow about 4 small plants at a time. But the PFC is simply the home version of what MIT is really building at OpenAg. The PFC is like a test platform to get us geeks involved and improve the system. The lessons learned in the small scale are being put to use in Food Servers. The servers are built in shipping containers, using the same hardware and software. This is all happening now, in the new lab that OpenAg has just opened. The next phase is the Food Datacenter, which scales the project to warehouse size. The scalability is built into the project, so it’s instantly scalable without having to be reimagined.

Servers and Datacenters can be deployed in various ways. They have a home in climates that don’t support standard agriculture, they have a home where food is scarce and people are hungry. In America, they have a home in the city. According to the census bureau (in early 2015), 62.7% of our population lived in the city, and cities make up 3.5% of our land. The food to feed our population often travels an enormous distance. The urban agriculture push seeks to change that. We see more city gardens and roof gardens, but it’s not enough. There is talk of entire floors of skyscrapers becoming farms. This is where food computers can play a role.

So what is my plan?

I am WAY into the whole food computer concept, and I hope to contribute to the initiative ASAP, but I am financially challenged. They are working hard to make a system that is affordable to build, but obviously this system will presumably lack some of the higher tech solutions that MIT is deploying in their own systems. I’m keeping my eye on their progress, and buying what I can, when I can, in order to deploy a PFC. But I’m not spending my time idly, I’m building my own hydroponic system.

Armed with a prime directive of feeding myself, the PFC is taking a necessarily secondary position, but I’m keeping it’s spirit nearby. The systems I’m designing to control my growing environment are taking their cues from the PFC. I’m trying to keep my equipment selection to PFC compatible options. Eventually, I hope my system will run on the food computer software. In that sense, I’m skipping the PFC and going straight to the food server, though I do plan on having a dedicated PFC as well.

I already have about 80% of my hydroponic operation setup, and hope to be starting seeds by the end of the year. Naturally, I will be writing about the journey as it unfolds.

Keep making stuff (and remember, growing food counts as making stuff!)

Love it Shawn. Not only are you a genius at technical stuff, you’re an amazing writer. Love you and can’t wait to see you for Adam’s wedding.